Clearing the Way: How Duke Staff Helped Deliver a Life-Saving Treatment Through Ice and Snow

Vital medical treatment for a child had only one approved route – by foot

“This request is not due to normal safety reasons,” Flanagan wrote. “Anything we can do to make the walk as safe and secure as possible could be the difference between a child receiving this treatment and their life being saved, or them not receiving the treatment.”

“Life saved” and “child” jumped out to Washington. In the office, she saw Wilford Hamm, a Grounds Equipment Operator, who was refueling machinery after clearing that pathway outside Duke North Pavilion.

Hamm explained that he and his colleague Dan Farrar had cleaned that small stretch of sidewalk. But with the new information, Washington told them they needed to clear a longer path.

And the clock had already started on whether that life-saving treatment could be delivered in time.

Transporting Treatment by Foot

In 2016, Duke University entered into a licensing agreement with a biopharmaceutical company called Enzyvant to produce a treatment for children born without a thymus, essentially resulting in no immune system. Developed from research by Duke Professor Emeritus of Pediatrics Mary Louise Markert, the treatment called RETHYMIC uses donated thymus tissue that is processed for up to 21 days and implanted in a patient, typically a child suffering from a genetic condition called DiGeorge Syndrome.

RETHYMIC treatment was approved by the U.S. Food and Drug Administration in 2021, and Duke University is the only place in the United States where it is administered, said Beth Shaz, MC3 Deputy Director. About 20 to 25 children receive the treatment at Duke each year.

“This is an incredible example of how Duke research saves lives,” Shaz said.

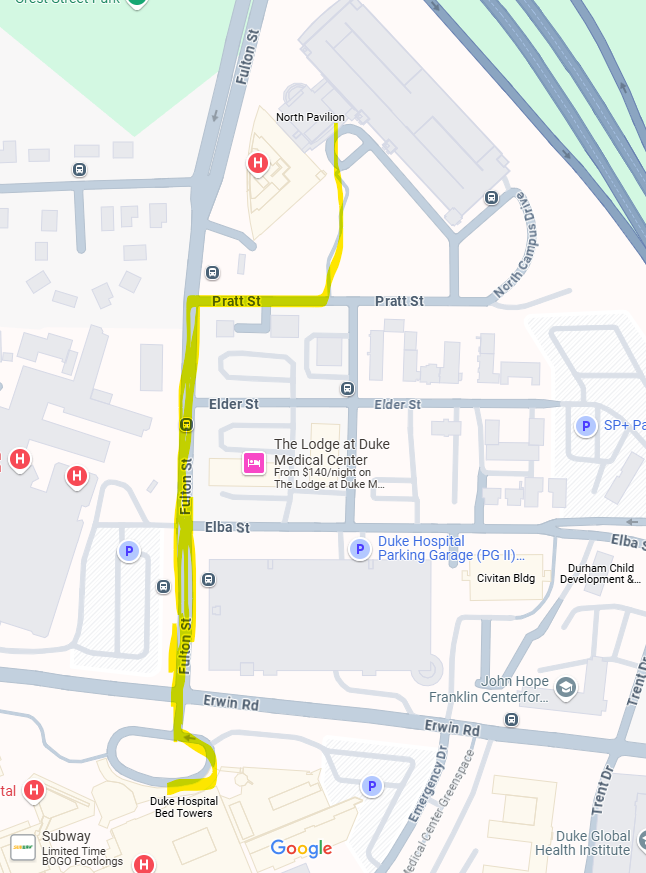

There are specific regulations around how the treatment is manufactured and transported, however. The only FDA-approved way to transport it from Duke North Pavilion, where it is manufactured, to Duke University Hospital, where it is surgically implanted, is by foot.

The treatment must be walked that three-tenths of a mile, delivered in a cooler, by a team of three to five people. The tissue is in a container with liquid that cannot be tilted or leaked. It must be carried steadily.

“I know it sounds ridiculous, but if we tried to just throw it in a car and drive it down, it would invalidate the product, and we wouldn’t be able to deliver it to this child who is very, very sick,” Flanagan said. “A helicopter couldn’t land and pick it up. A car couldn’t drive it over. There’s only one validated way approved by the FDA and you can’t deviate from that at all.”

And on Feb. 20 that pathway was covered with ice – with surgery planned on a child at 2 p.m.

“There was no option to wait a day and wait for better weather because of all the things in motion,” said Flanagan, the Director of GMP Manufacturing at MC3. “We’ve done all this preparation, and we’ve got a child who’s very, very sick who came all the way here to get this treatment. We can’t not treat them.”

The Work to Clear

Wilford Hamm remembers what the pathway was like when he first went out to clear it in the morning.

“Oh man, it was nothing but ice,” he said. “We had about 2 inches of ice.”

He and fellow Grounds Equipment Operator Dan Farrar worked to clear it with a mixture of sand and salt, shovels and perspiration. But after hearing from Washington about what, exactly, the path needed to be cleared for, they returned with renewed determination.

“It was all-hands-on-deck for anyone that was available to do it at the time,” Hamm said.

The only thing everyone needed to hear was that it was all for a child in need.

“When they heard that it was something that had to deal with a child, they took that opportunity and really jumped in,” said Scott Thompson, Duke’s Director of Landscape Services. “That was all they needed to know.”

More help from Duke Landscape Services was called in to quickly tackle the sidewalks. Assistant Horticulturalist Terrence Williams delivered equipment and materials to the site, Grounds Equipment Operator Trevor Holman maneuvered what Facilities calls “brooms,” a machine that swept away snow and ice from the path, and Landscape Specialist Derik Franklin started clearing crosswalks that were technically the responsibility of the city of Durham but needed to be cleaned for that direct path to the hospital.

“Everybody dug in to make sure it got done,” Washington said. “This is what sets us apart. It’s Duke. We’ve got to get them from Point A to Point B, and that’s what we have to do.”

It was more than an hour of hard work, Hamm said, before the pathway was completely cleared. Franklin went back over it twice, scattering a layer of salt to make sure nothing was slippery.

When Flanagan went out around lunchtime to assess whether his crew could deliver the treatment on time, he was stunned at the difference in a matter of hours.

“Areas that were literally ice were cleared,” Flanagan said. “There was nothing on them. Between where we started and where we ended, there was not one piece of ice.”

The Teamwork

About 100 people touch the process of manufacturing and administering this life-saving treatment, ensuring the child can receive the treatment and receive care afterward, MC3 Deputy Director Beth Shaz said. Between the pediatric cardiac surgery team securing the donor tissue, the pediatric transplant and cellular therapy team caring for the recipient, members of MC3 and Office of Regulatory Affairs and Quality (ORAQ), the pathology department and the pediatric surgery team that performs the implantation, it all adds up. Each step of the manufacturing and administration process is performed at a prescribed time – especially that final stage of surgical implantation.

“It's a very coordinated ballet on multiple fronts,” Flanagan said. “Once we tell the pediatric surgical team we're going to try to hit a certain time, we don't like to be late, and they don't like us to be late because this involves very small children.

“Any delays if the sidewalks were bad and we had to take a long time, it would have shortened the amount of time that they had to actually perform the surgery because that clock would have ticked down even more. Any additional time that gets eaten off that clock for things like a slower walk would be impactful to the surgical team and being able to treat the child.”

In February, that number involved in the safe delivery of the treatment grew by about seven more with the crew in Facilities who ensured the treatment could be delivered and the surgery could be performed. Flanagan said the story still brings tears to his eyes whenever he retells it.

“This was such a great collaboration of teamwork, from receiving the call to the clearing of the sidewalks,” Washington wrote in an email to her colleagues afterward.

“There is nothing we can't do when we work together.”

Got a story idea or shout-out? Send your news and photographs through our story idea form or write working@duke.edu.

Follow Working@Duke on X (Twitter), Facebook and Instagram and subscribe on YouTube.